Earl Zausmer's BMW 540

Updated April 2022

May 2022 -- "CarMiza Introduction" by Mike Michne

April 2022 -- "One red car" -- Earl Zausmer interview by SQology

|

It's rare to win over 90% of all car audio competitions entered in a 5-year period ("best of show", "best in class", "best sound") and even more rare to be featured not only in all of the major car audio magazines but also to appear in Time, on MTV and CNBC, and in more than 211 newspapers in the US as well as 27 magazines worldwide, yet that's only part of the acclaim and attention awarded to Earl Zausmer's BMW 540i which undoubtedly ranks as one of the most widely publicized car audio systems ever.

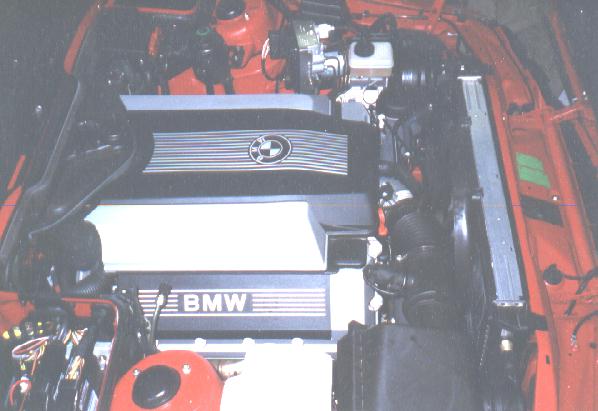

Below are some articles detailing Earl's legendary car audio system, which sports two gold-plated Milbert BaM-235 vacuum tube amplifiers among other unique audio goodies. Feb 2005 update: Five years ago Earl exited car audio and sold his famous car after moving to Arizona. The car's story since is as colorful as its various owners, which included a gold- and platinum-record awarded musician, vintage audiophile and member of the "Golden Boldens," who fortuitously intervened, and for whom we will always be thankful for, to save the car from oblivion. In February, 2005 we purchased the car from a nice Christian family in Oregon for use as a demo and reference system.

Components: Features:

|

|

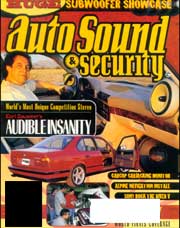

| Auto Sound & Security magazine, February, 1999 |

|

| Time Digital magazine, November 3, 1997 |

|

| BMW Roundel magazine, February, 1996 |

|

| Car Audio & Electronics magazine, February 1995 |

|

| Autosound & Security magazine, December 1994 |

|

| Various newspaper articles | |||

|

|||

|

Text from Philadelphia and Detroit area newspapers.

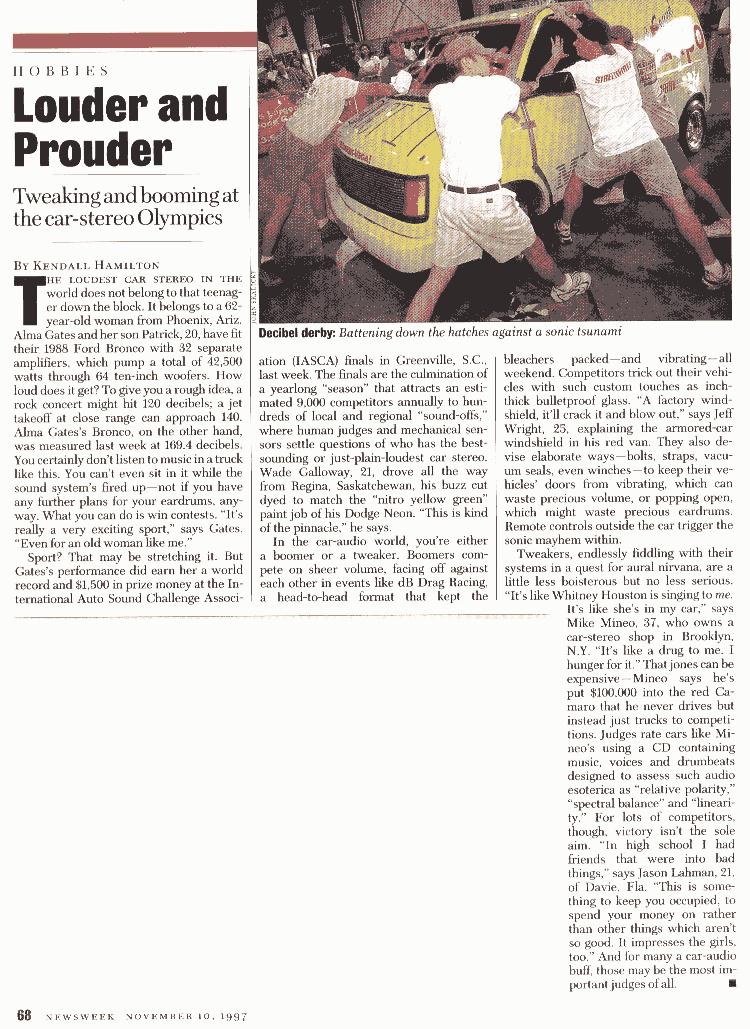

Building the perfect car stereo system for an audiophile

When Earl Zausmer turnedon the $30,000 stereo system in his BMW 540i, four speakers rose from cavities in the dashboard, and a vibrant red laser beam came to rest on the right side of my face. "Ideally, it should hit you right in the ear," Zausmer noted. The purpose of the laser, he explained, is to make sure the sound is being delivered directly to the listener. Conventional stereo systems might bounce the sound off dozens of distorting surfaces inside the car before laying it on the doorstep of your tympanic membrane. But with the help of the laser, Zausmer's puts it right on the aural money. That ability to put the music in the right place is part of the reason Zausmer's sound system is easily the best this layman has ever heard. It also figures in the way the system has been received by the experts. Zausmer's system recently achieved the highest overall point total in sound quality at the International Auto Sound Competition Association (IASCA) finals in Dallas. "For us audiophiles, the IASCA finals are the Olympics," observed a beaming Zausmer. Zausmer, the head of a trucking company based in Havertown, Pa., is a boyish 42. He has been an audiophile since he was a truly boyish 15. According to Zausmer, audiophiles don't just love music, they require it. "Audiophiles are people who need music to calm their nerves. That's the way we are." For most of his audiophiliac past, Zausmer's hobby has been building home sound systems. But in recent years, his avocation has taken an automotive turn. That makes perfect sense, since he spends so much time driving around the Northeast, calling on customers. His interest in building an automotive system led him to the competitions, and an active role in the auto audio community. The auto-sound community is a growing avocational subculture, according to Bill Burton, technical director at Car Audio and Electronics, which has a circulation of 100,000 and counting. The hobby is popular in this country, and big in Europe, Japan and Canada. Like so many of his fellow travelers, Zausmer enjoys the social as well as the competitive aspects of the judged shows he enters. After the day's competition, for example, he and fellow competitors go out and have some fun. "We don't go to bars and stuff like that, and our wives know that. We'll go out to dinner together and talk about stereo systems." In the case of Zausmer's system, that requires a good deal of fat chewing. The installation (audiophiles call it "the install") of Zausmer's system required about $30,000 and about 1,800 hours of professional help. "We ripped apart most of the car," Zausmer recalls. The process included taking off the front fenders and welding a set of 13-inch woofer, or bass, speakers in the steel structure behind each of the kick panels. "The woofers are welded to the car. That's why you feel the bass notes through your feet. ... In effect, you're inside the speaker cabinet." Fenders, doors, floors and roof were covered with 370 piounds of a special sound-deadening insulation made of asphalt and butyl. Next, motorized little elevators were fabricated to lift $5,000 worth of high and midrange speakers from their "silos" on each side of the dash. The high-range speakers (tweeters) are B&W Silver Signatures, so named because their metal componentry is solid silver. "When you work with silver, you get better sound," Zausmer said. The speakers get their motivation from three amplifiers. One is a conventional Zapco solid-state unit that powers the woofers. The other two are Milbert vacuum tube units used to actuate the tweeters and midrange speakers. Vacuum tubes are long obsolete, of course, having been replaced decades ago by transistorized, or solid-state, technology. But they persist in the world of exotic audio electronics, Zausmer says, because they "make a gentler, less harsh sound" than solid-state devices. The speakers and amps work in tandem with two 10 CD players, one in the trunk, the other under the front seat. The whole system is tied together by a Sony ES control unit. Since the sound-quality competitions also take installation quality into consideration, Zausmer lavished a lot of attention on detail. Housings and connections were handsomely machined from brass and aluminum. Everything possible was done to make the installation neat, safe, and pleasing. Zausmer says original ideas, like welding the speakers to the car's front structure, added points to his score at the Dallas finals. So did his extensive efforts to make the installation as discreet as possible. What also helped Zausmer was his considerable gift for tuning stereo systems. Tuning is the key to winning. It doesn't matter how good yours components are if you can't get them to work together properly. Says Burton, whose magazine recently featured Zausmer's system: "Earl has a wonderful understanding of how to get what he wants." Apparently so, because the results are pretty stunning. When he plays music for you in his car, he make it seem as though you are listening in an intimate room -- or a cathedral. And the sound is so natural, pure and precise. I could hear the trumpet player's fingers hitting the valves during one selection. And the music is so wonderfully focused. It was as if the singers and musicians in the various recordings he played had carved out their own distinct turf on the dashboard. Unlike some of his fellow competitors, Zausmer doesn't treat his champion like a show car. He doesn't trailer it to the shows and keep it locked up in the garage when he's isn't competing. "If I have this great system, why shouldn't I listen to it?" he asks. "I really enjoy listening to it when I'm on the road. And sometimes, when I'm at home, I'll go out in the garage, get in the car, sit back, open a book, and listen to music." ### (c) 1995 Knight-Ridder Newspapers. Distributed by Knight-Ridder/Tribune Information Services. |

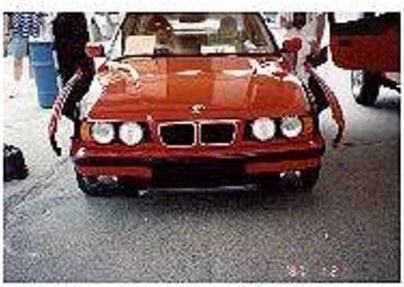

Earl's red BMW540i Version #2

It's rare to win over 90% of all car audio competitions entered in a 5-year period and even more rare to be featured not only in all of the major car audio magazines but also to appear in Time, on MTV and CNBC, and in more than 211 newspapers in the US as well as 27 magazines worldwide. Yet that is precisely what Earl Zausmer's 1994 BMW 540i and more than $20,000 of car audio/electronics hardware, as well as over 2,000 hours of installation work has accomplished. Some affectionately named Earl the "King of IASCA."

This 1994 BMW 540i rides on 17" Racing Dynamics wheels and Dinan suspension. According to the dyno, the Dinan chip boosts performance to 325hp and 318ft-lbs torque at the wheels.

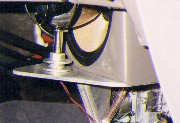

This car earned its reputation with features such as hinged fenders which fold open. Not just for show, they make it easier to access the front-mounted 15" subs.

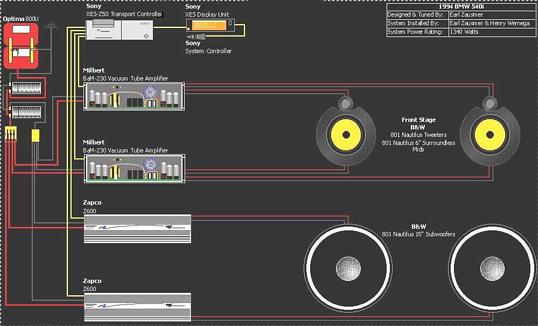

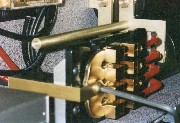

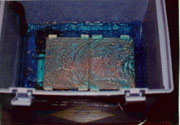

In the trunk, both Milbert BaM-235 vacuum tube amps are mounted for a unique look. One amp per channel (120W total on mids and highs). Both Zapco Z600 amps (driving the woofers) and the Sony XES CD changer are suspended from the rear deck by rods.

The Sony XES-Z50 head unit display was mounted into the mirror to keep it near eye level. This customization of the stock mirror required Bondo forming and lots of sanding. The smarts for the wireless remote, joystick and tuner all reside in the glovebox. All other DSP brains are in the main 10 disc changer in the trunk.

Two 15" B&W 801D woofers, each driven by a Zapco Z600, were mounted up-front (yes, 15"). In this location, as opposed to the rear where subs are usually mounted, the listener can literally feel the sound and air right in the face, and the resulting immediacy and coherence of the sound is breathtaking.

Passenger side view. Digital time alignment in the Sony XES and a red laser ear positioning guide ensure that frequencies are coherent and bass is taut, allowing rock music to kick listeners tightly in the chest at higher volumes.

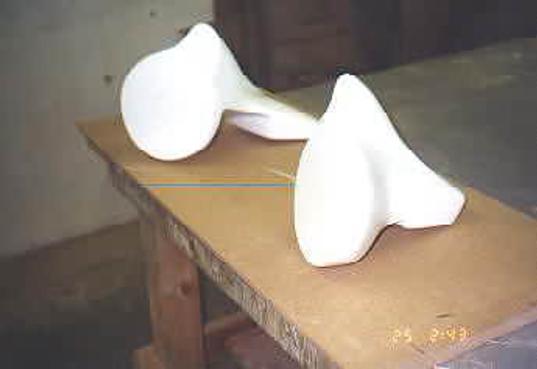

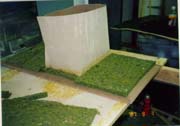

One design goal was to ensure as much sound as possible hit the listener before bouncing off other interior surfaces. This was accomplished by placing speaker pods in a top-of-dash position. Previously motorized to rise up out of the dash, these pods now sit stationary. Each pod holds a B&W Nautilus 801D 6" FST Kevlar midrange and Silver Signature tweeter. The speaker pods were inspired by the B&W Nautilus seashell design, and in this picture they are ready to be fiberglassed.

The halogen lights, antenna, and Sony XES-Z50 fuse use the rear deck fuse block, which was placed under the rear stock speaker grill. Larger fusing is near the batteries, near the capacitors and behind the amps in the trunk. Thick, stranded Street Wires power cabling is used throughout.

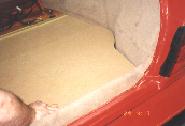

The customized rear seat can easily be removed, revealing carpet and fiberglass work and batteries. Dynamat layers cover the metal chassis underneath. Everything is independently fused, capped and powered by thicker-than-necessary cables.

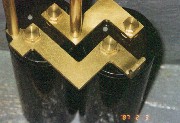

Close-up view of the Optima batteries powering the Milbert amps and other trunk-mounted electronics. These sealed batteries are fitted with gold-plated buss bars as well as custom caps that vent any gases to the outside, per IASCA regulations.

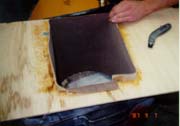

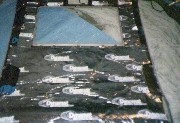

Dynamat was applied generously throughout the car to maximize sound deadening. There are no rattles, buzzes, or reverberations.

Layers of Dynamat in the trunk lid. All other body panels are multiply coated. The trunk, hood and four doors feel heavy and close with a solid thud.

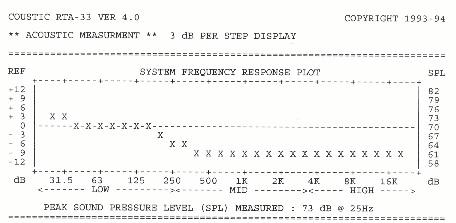

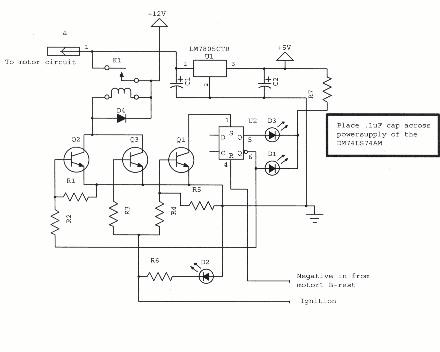

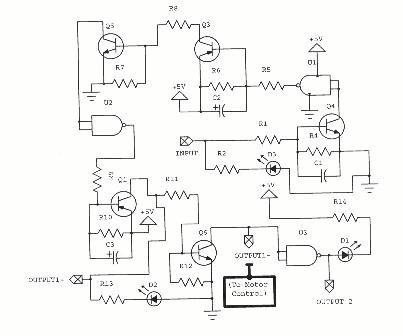

System wiring diagram. Each Milbert tube amp needs 5 amperes ... about the same as one headlight. The other electronics consume about 5 amperes, for a total system idle power consumption of 15 amperes.

| Version #1, from Earl's original site, courtesy Earl Zausmer and Jason Abott | ||||

|

||||

| Battery Mounts & Machining | ||||

|

||||

| Capacitors & Rear Power | ||||

|

||||

| Carpeting | ||||

|

||||

| Dashboard | ||||

|

||||

| Rear Deck | ||||

|

||||

| Deflex Absorption | ||||

|

||||

| Dynamat | ||||

|

||||

| Fenders & Subwoofer Mounting | ||||

|

||||

| Floor | ||||

|

||||

| Fuses | ||||

|

||||

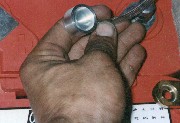

| AU Spells GOLD | ||||

|

||||

| Head Unit & Stalk | ||||

|

||||

| Mirror & Display | ||||

|

||||

| Motorized Speaker Pods | ||||

|

||||

| Rear Seat | ||||

|

||||

| Speaker Pods | ||||

|

||||

| Speakers | ||||

|

||||

| Subwoofers | ||||

|

||||

| Trunk | ||||

|

||||

| Wood | ||||

| ||||

| Update September 2012 | ||||

|

||||

Photo Descriptions

Photo Descriptions